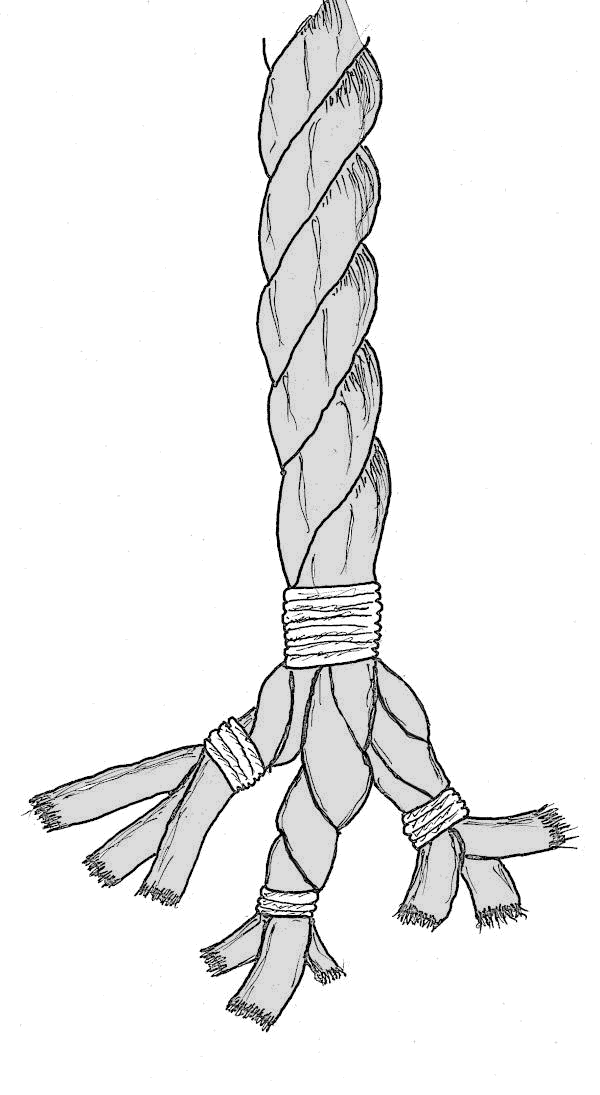

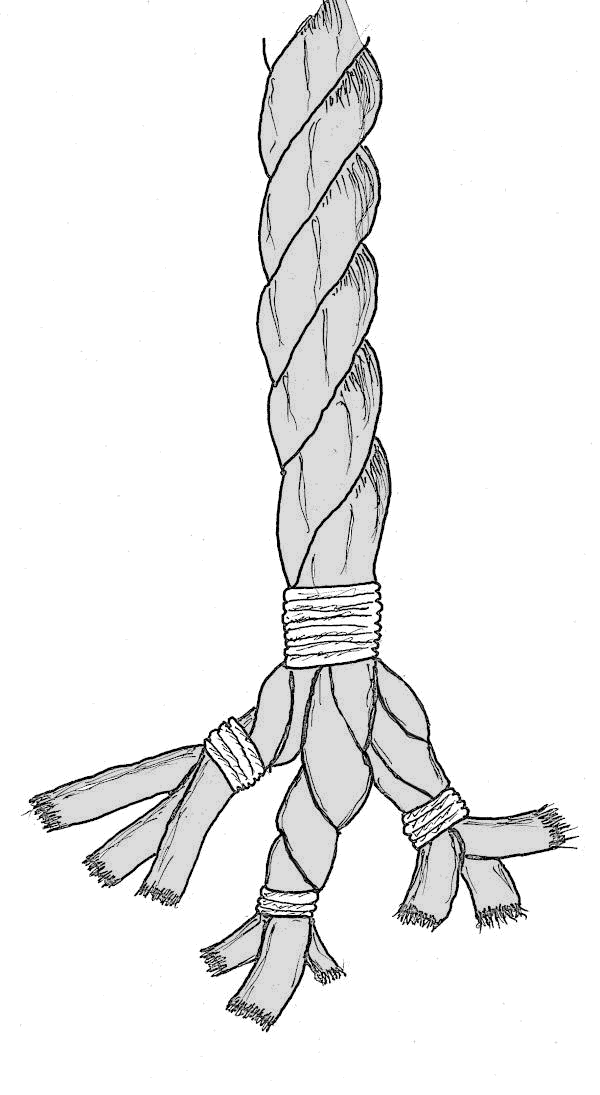

(Twisted)

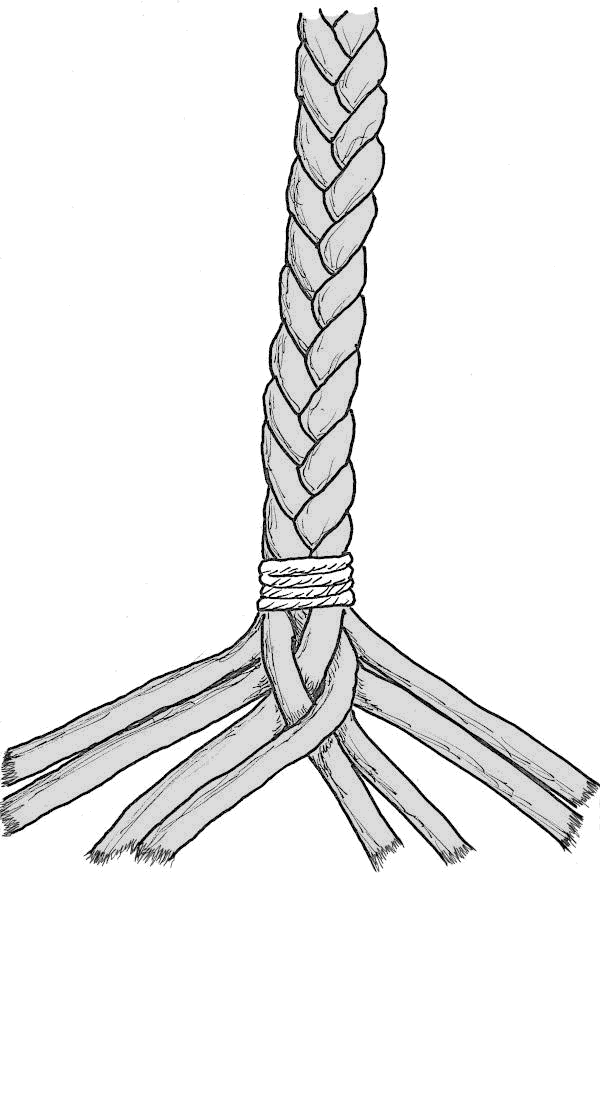

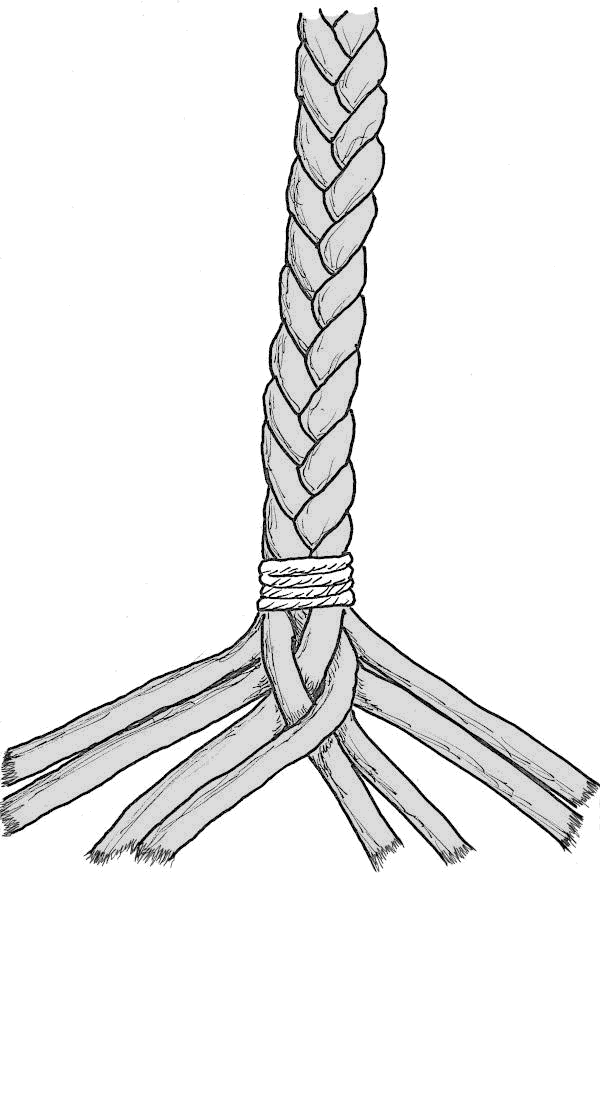

(Braided)

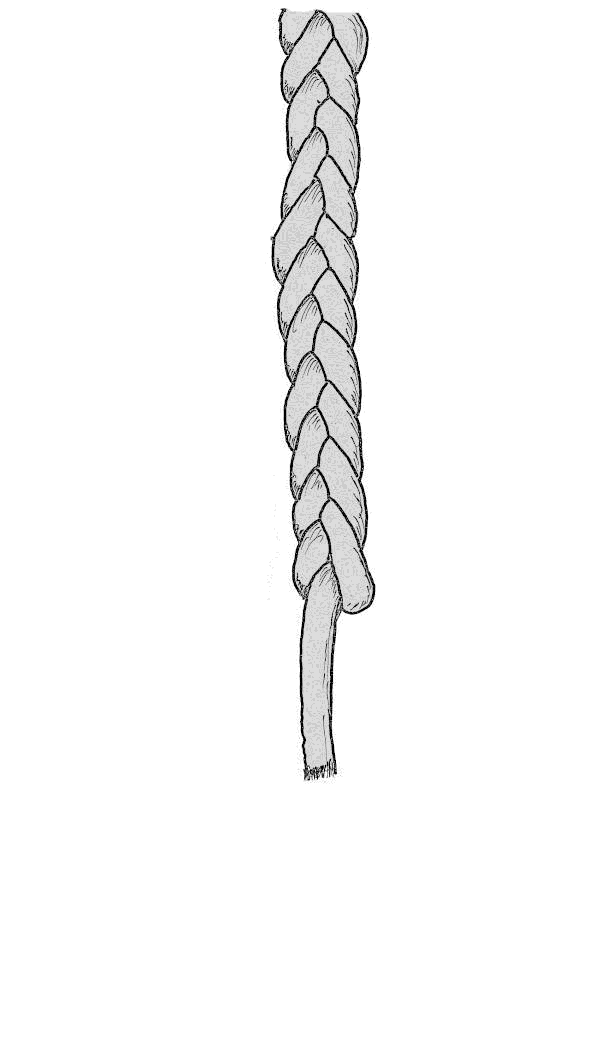

(Knit)

| Chapter 1 | Introduction | Chapter 3 |

Rope is a collection of short, small fibers arranged into a tight, sturdy structure that is larger, longer, and stronger than any of the original fibers.

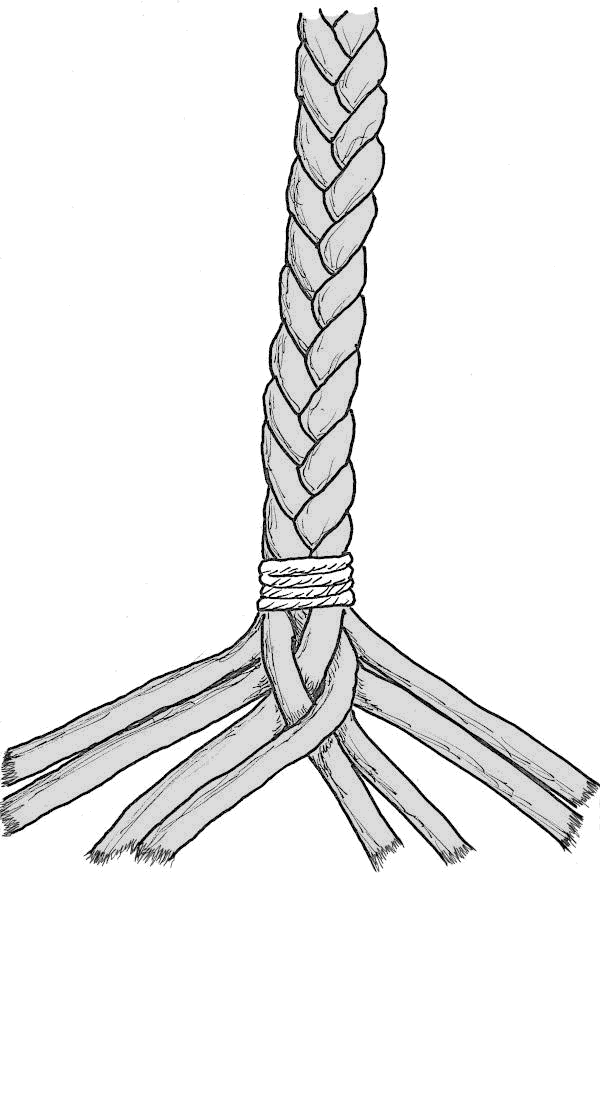

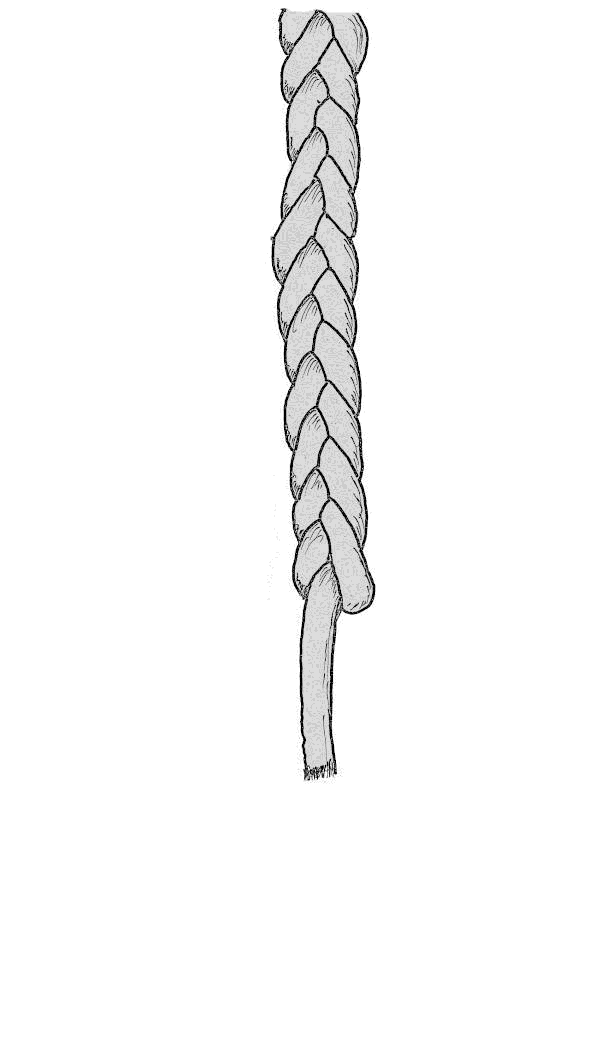

Rope can be made by either twisting, plaiting (braiding), or knitting.

|

|

|

| Three Strand, Three-ply (Twisted) |

Eight Strand Square Plait (Braided) |

Lucet Made (Knit) |

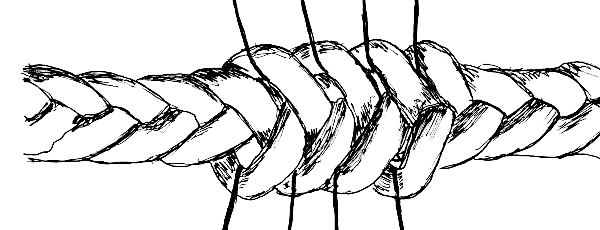

In Figure 2.1 above, the three different structures are roughly the same thickness. Three-ply twisted rope is a rounded triangle in cross section, the other two are square. Eight strand square plait and lucet knit are very similar in outward appearance. Given a sample from the center of either cord, you can only distinguish the two by spreading the yarns and inspecting the inner form. The knit cord will have crossing strands, shaded below in Figure 2.2, just under the surface. These are not present in the plaited cord.

Figure 2.2: Dissection of Knit Cord (top), Eight Strand Plait (bottom).

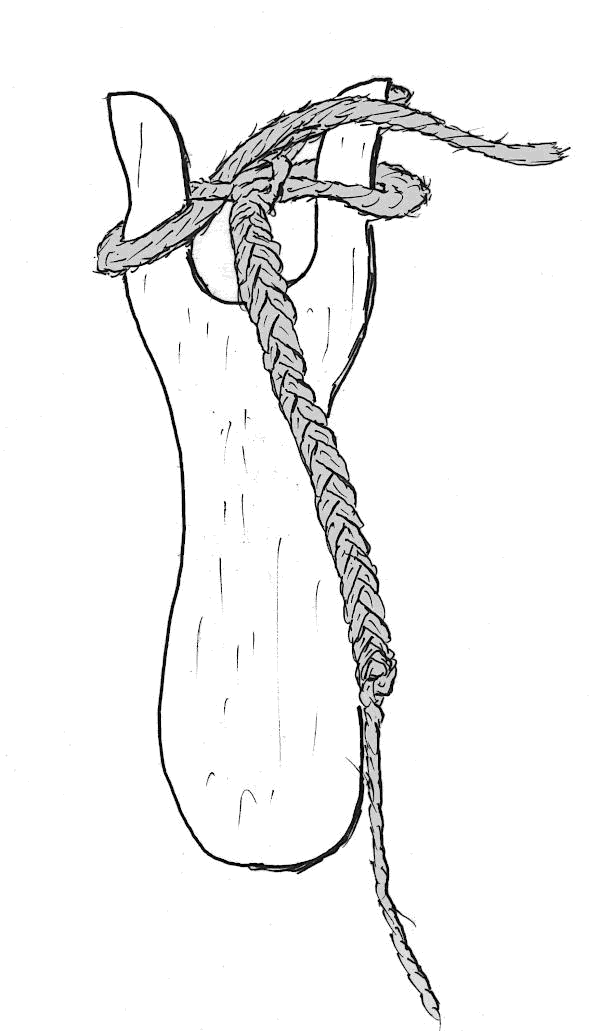

Figure 2.3: Lucet. (ABOK #2875)

Knitting is only used in "small stuff", due to the tight bends in the construction. Using only a lucet and a ball of yarn, you can take your cordage making anywhere, and work whenever you have free time. This type of knit rope was mostly used for lacing up clothing.[218] [675]

Figure 2.4 : Eight Strand Square Plait.

(ABOK #3001)

The disadvantage with plaiting rope is the time required, and the difficulty of making long cords.[630] You have to control the free ends of your yarns while plaiting, or they tangle almost immediately. Yarns on bobbins or spools help keep the ends from fouling, but are awkward when working heavy, or long strands.

The Ashley Book of Knots (ABOK)[040] has dozens of other "Plat Sinnets".

Although wind and water mills had been used for centuries for tasks like pumping water, grinding grain, and even sawing wood, it wasn't until the Industrial Revolution[775] that power came to ropemaking. There are several reasons for this. The first is that most rope production happened near ports, because sailing ships were the biggest market. The land around East Coast ports is mostly flat, the rivers are slow and tidal. These conditions make it difficult to power a water wheel.

Another factor is the variety of twisting operations taking place at the ropewalk. Grinding grain is a one-speed operation. Spinning rope yarns requires a fast turning spindle, but no great power requirement. Laying up a great anchor cable, on the other hand, requires a very high torque, and slow, even twist. And there are needs for everything in between. This would either require a variable speed transmission, or separate lines each with its own gearing. That's a large investment in heavy machinery. Man power was much cheaper, you can employ the men you need, when and where they are needed. Men are more adaptable than machines. One man can turn a wheel, or twist fibers, or work with others to turn big cranks.

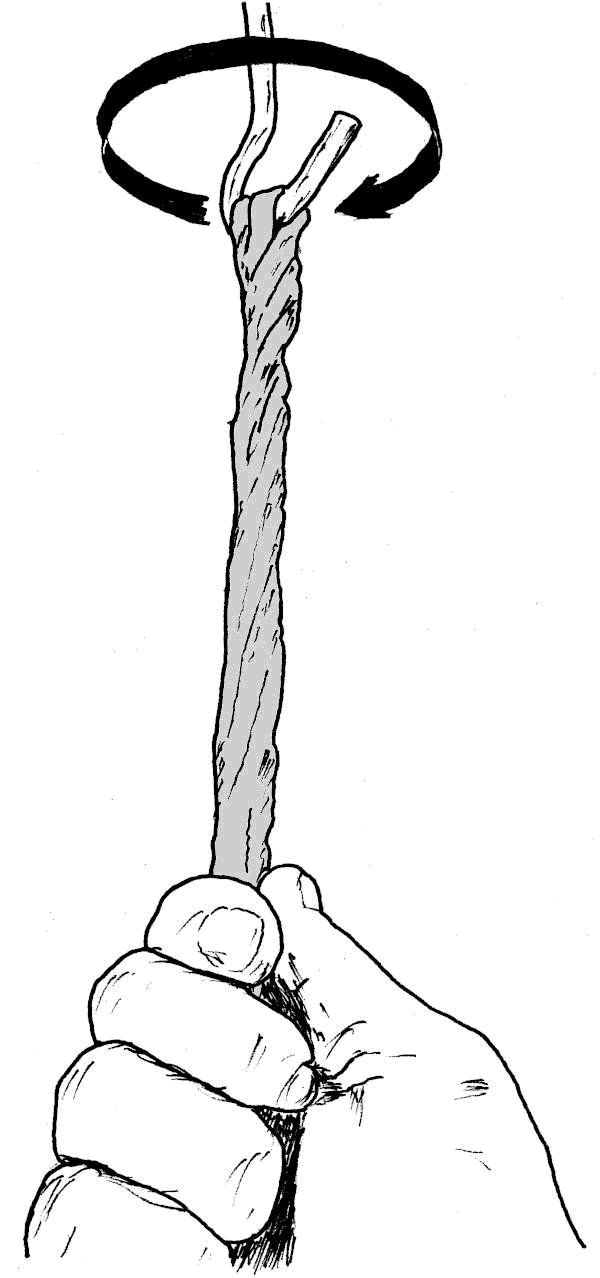

On the left side of Figure 2.5 is a bundle of fibers. The fibers are twisted together to the right to make a yarn. Then three yarns are twisted together to the left to make a strand. Next, three strands are twisted together, back to the right to make a rope. Finally, three ropes are often twisted to the left to make a cable.

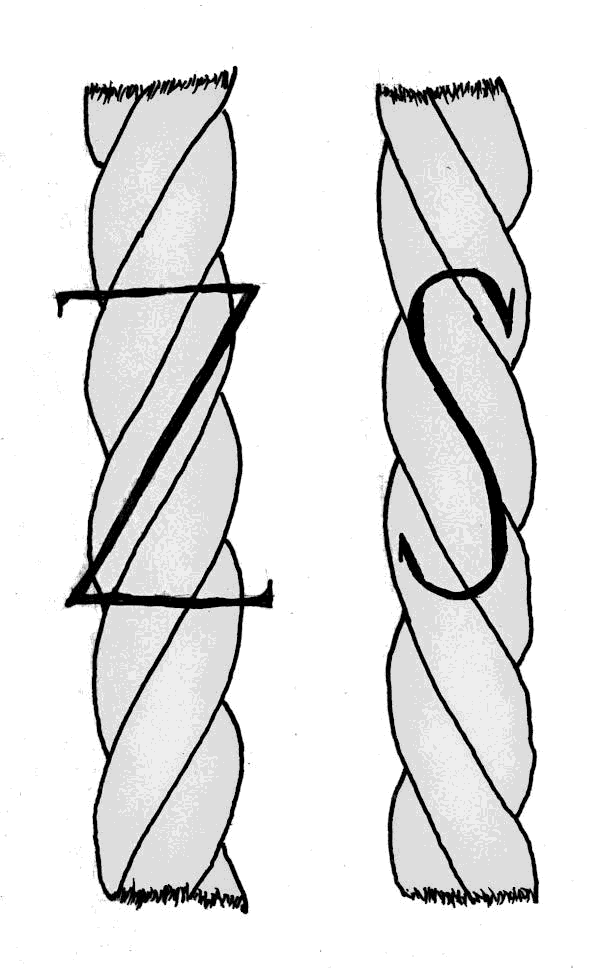

Figure 2.6: Twist Directions.

"S Twist" and "Z Twist" are the approved designations of the ASTM International (formerly known as the American Society for Testing and Materials) and the International Organization for Standardization (ISO). These are not Colonial period terms. These terms were adopted in the 20th Century to avoid confusion over terms like "right twist", "left twist", "clockwise", and "anticlockwise", terms you will often see in texts.

"S" and "Z" twist describe the shape of the rope, whereas right twist and left twist describe the process used in making the rope.

|

|

| Crank Twisting Clockwise. | Hand Twisting Clockwise. |

| Figure 2.7: Twist Perspective. |

But the description depends on which part of the process you are talking about. If you are holding a handful of fibers, facing a crank, and the crank is turning clockwise (to the right), the bundle will get a Z twist, as shown in Figure 2.7 (left), above. If, on the other hand, the hook is stationary, and you are twisting the bundle of fibers clockwise (to the right) with your hand, the fibers get an S twist. You do not have to look very far to find a Z twist described as right twist, and left twist, and clockwise and anticlockwise.[495] This Bibliography of Twist gives an indication of the various contradictory definitions of twist direction.

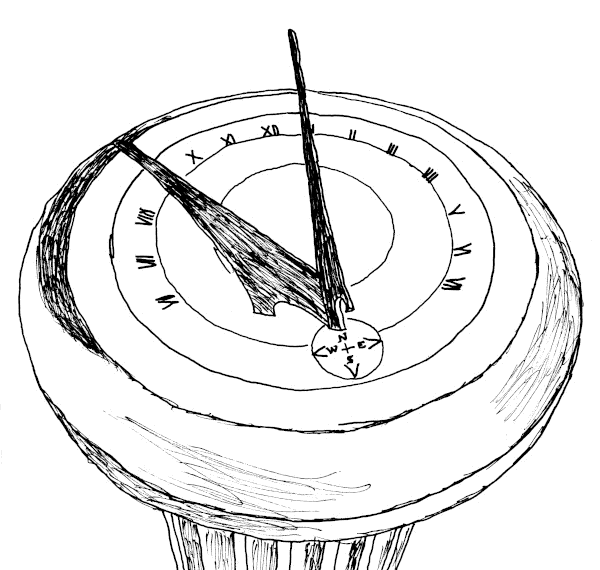

Older texts talk of ropes laid "with the Sun".[215] [585] The Sun rises in the East, moves South, then sets in the West, and its shadow on a sundial travels West to North and then East. Clocks were designed so the hour hand mimics the motion of the gnomon's shadow. With the Sun, or with the Sun's shadow, is clockwise. But as just noted, clockwise can have two meanings when twisting fibers.

Figure 2.8 : Sundial - With the Sun.

Shakespeare (1564 – 1616)[744] mentions clocks frequently in his plays but the fact is, in the American Colonies, in the late 1700s, clocks were still fairly rare. In 1752, Benjamin Banneker made one of the first clocks in Maryland. He carved it out of wood. The first public clock in Maryland was installed, in Frederick, in 1791. Virginia didn't get a public clock until the 1820s.

Samuel Johnson's 1755 Dictionary[468] defines the clock as, "The instrument which, by a series of mechanical movements, tells the hour by a stroke upon a bell." No mention of hands nor which way they turn.

According to the Oxford English Dictionary, the word "clockwise" did not exist until after 1800.

If you said the word "clock", to a Scottish immigrant in the 18th Century, you would be understood to be talking about a "cloak", or the noise a chicken makes - "cluck", or one of several large beetles.[251]

So if you are holding the loose ends of the fibers and want an S twisted yarn, then the crank has to turn

counter clockwise, from your point of view.

But if you are giving instructions to the person turning the crank, you have to reverse your instructions

since they are facing the crank from the other direction. From their perspective, they have to turn the

crank clockwise.

Unless the crank they are turning is driving the hooks with gears.

But that depends on how the gears are arranged....

It is easier to just show your cranker which direction to crank by making big hand circles.

| Chapter 1 | Introduction | Chapter 3 |

| Colophon | Contacts |