| Chapter 2 | Introduction | Chapter 4 |

A single-ply rope is called a yarn. This is the basis of all rope making. Twisting is what keeps a bunch of short, individual fibers from falling apart into a tangled nest of fluff.

|

|

|

|

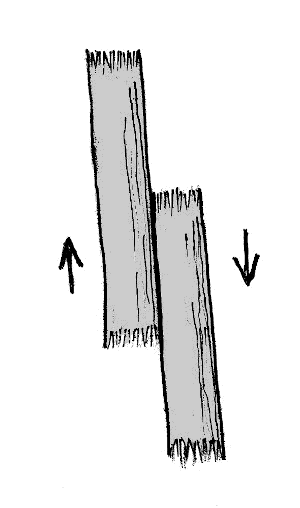

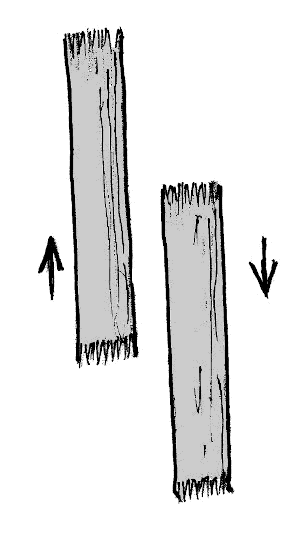

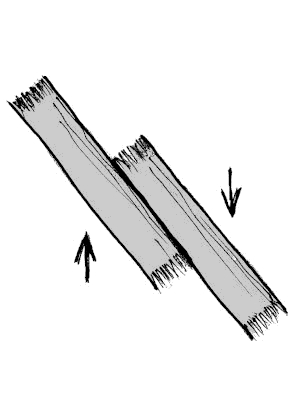

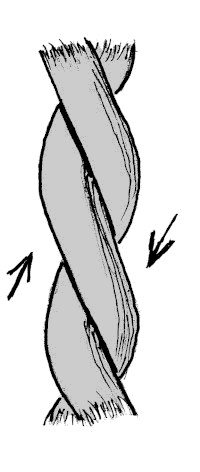

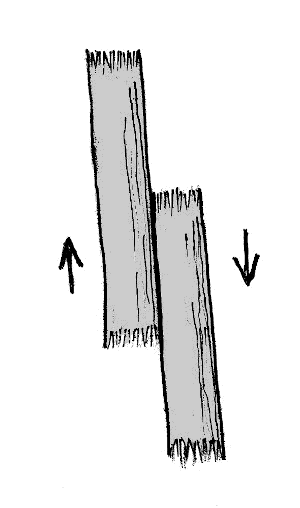

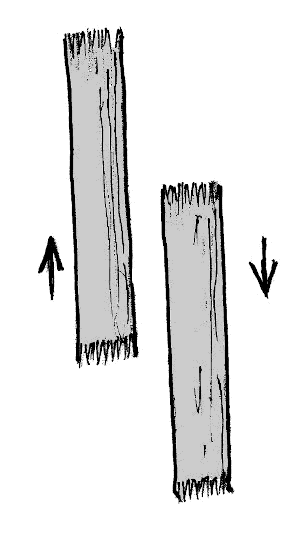

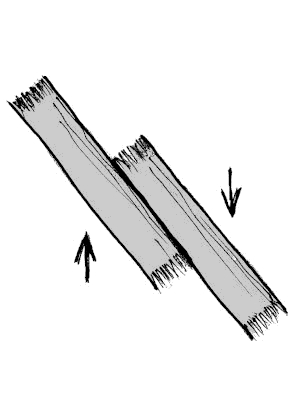

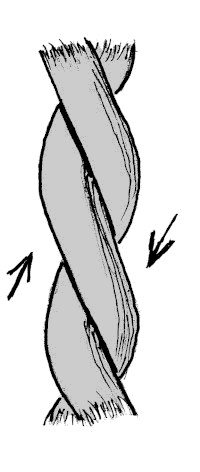

| (A) | (B) | (C) | (D) |

| Figure 3.1: Friction Between Fibers. |

Figure 3.1 (A), shows two fibers side by side, being pulled in opposite directions.

Where they are in contact, there will be friction, reducing slippage.

How much friction depends on how much overlap there is between the fibers, how smooth

the fibers are, and how much force is pushing the fibers together.

Figure 3.1 (B), just shows that if the fibers aren't pushed together somehow, there's

nothing to keep them from sliding past each other.

(C) shows the two fibers oriented at an angle to the pulling

forces. Here, part of the force is pushing the two fibers closer together,

increasing the friction, and decreasing slippage.

And section (D) shows the two fibers twisted around each other. The twisting

forces the fibers into maximum side-to-side contact, from every direction perpendicular to the yarn axis,

preventing the fibers from sliding past each other.

But the fibers in a twisted yarn will tend to un-twist unless there is something holding the ends in place, or it is wound around something else. In many applications, this isn't a problem. Tying down thatch on a roof, and tying up the harvest, for example, are cases where single-ply yarns are completely satisfactory.[890]

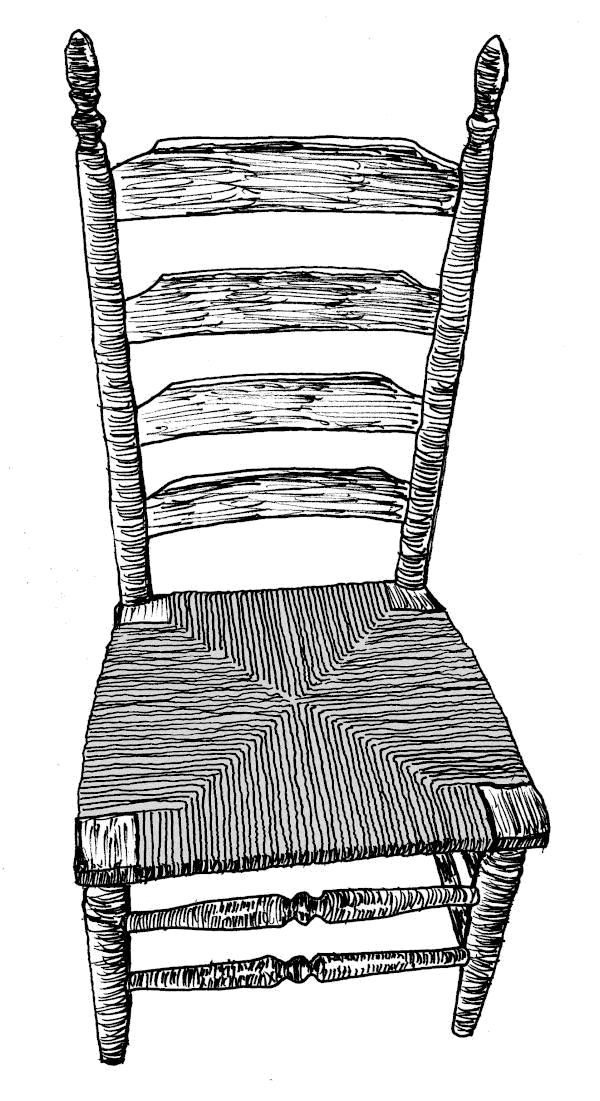

A single-ply yarn, especially when made from straw, is called a sugan, sugane, sugainn, suggane, súgán, or shúgáin in Ireland. The Scots call it a sookan, soogan, or a soucan.[251] In Ireland, "súgán" is used to make the seats of súgán chairs, similar to rush seats common in American and English chairs which became popular in the middle 1700s.[595]

Figure 3.2: Chair with Single-ply Cord Seat.

In Scotland, in addition to all the other uses, straw yarn was wrapped around the tops of shoes and up the leg as "strae-buits" (straw boots) to protect the wearer from snow.[251] England, Scotland, Ireland, and the Isle of Man provided many indentured and convict laborers to the Colonies. These places also relied on home-made ropes to keep the thatching on the roof of the house.[915] Everyone knew how to make rope.

In the British Isles, rope making was a social event, when neighbors would gather in the evening to make ropes for their roofs and to bind up the harvest. One person turned a crank or crook, and another sat by a pile of straw, adding new material while the twister twisted. As the rope grew longer, the twister had to move backwards to keep the yarn taut. With very small houses, the twister often ended up outside. Getting the twister out of the house is a popular plot element in many local stories. A young lady gets a younger sibling to turn the crank so she can have some private time with her suitor. Or a young woman's parents use the same ploy to get rid of an unsuitable suitor.[930]

band-hook, band-maker, band-spinner, bond-spinner, band-twirler, band-twister, band-finder, belly-auger, binder, bind-hook, bond-hook, bind-turner, bind-twister, bond-hook, bond-maker, bond-spinner, bond-turner, bond-twister, bond-winch, bond-winder, bowl-turner, crank, hand-fork, hay-hand-maker, hay-band-twister, hay-rake, hay-tweezers, hay-twister, hook, jenny, pair of cranks, pair of twisters, rake, rope-maker, rope-winder, scud, scud-winder, sime-twiner, sime-twister, sked, sked-binder, sked-winder, spindle-hook, spinner, spinning-jenny, straw-hook, straw-rope-twister, straw-spinner, straw-turner, straw-twiner, straw-twister, straw-whipple, straw-winder, swintle, swivel, thime-spinner, thraw-crook, turnel, turner, turner-up, tweezers, twiddler, twiner, twister(s), twisting-wire, twizzler, whankie, whim-wham, whipple, wimble, winch, winder, windlass, wink.

And that was just the English. The Scots and Irish have their own particular names for these tools.

Other cultures have produced other tools to spin ropeyarn. Follow these links until I get around to documenting those methods.

Generally, yarn twisting tools, used in the American Colonies, can be divided into five basic groups, based on shape and manner of operation: crooks, cranks, reels, spinners, and wheels.

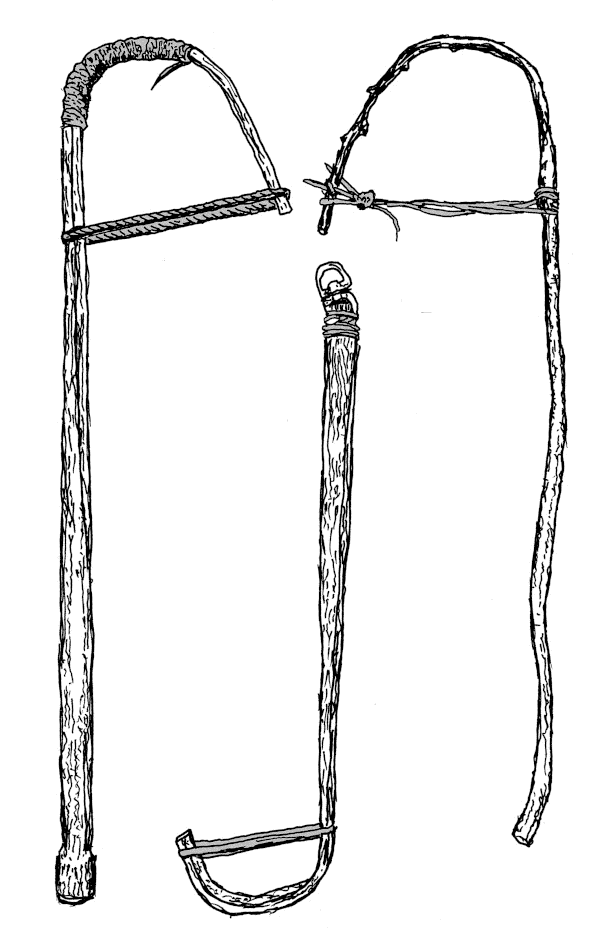

Figure 3.3: Bent Hickory Crook (left), Bent Hickory Crook with "Store" Swivel (center), Bent Twig (right).

Crooks resemble a shepherd's crook, with a cord tied across the hook part.

These can also be called: crúcan, or croakeen, corthsagan, thraw-hook, thrawcruk, thraw crwik. The "throw" part meaning to twist or entwine.[251] [267] [790]

This tool is mostly found in places the Romans never conquered, like Scotland and Ireland. The shape lets the spinner twist faster, with more torque, and more smoothly than can be done with just your fingers.

The fibers to be twisted are looped around the end of the crook part, just outside the crossing string. The pivot hand, that furthest from the fibers, is in-line with the cord to be twisted. The shape of the crook puts the twisting hand, closest to the fibers, off axis. This gives leverage for higher torque, and allows more muscles to be brought into play than just twisting with the fingers.

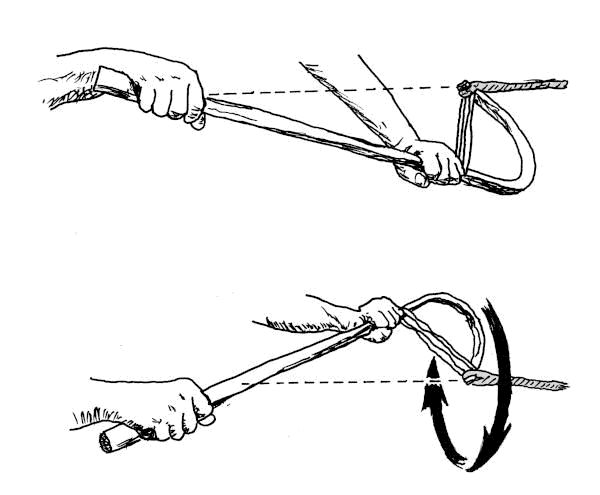

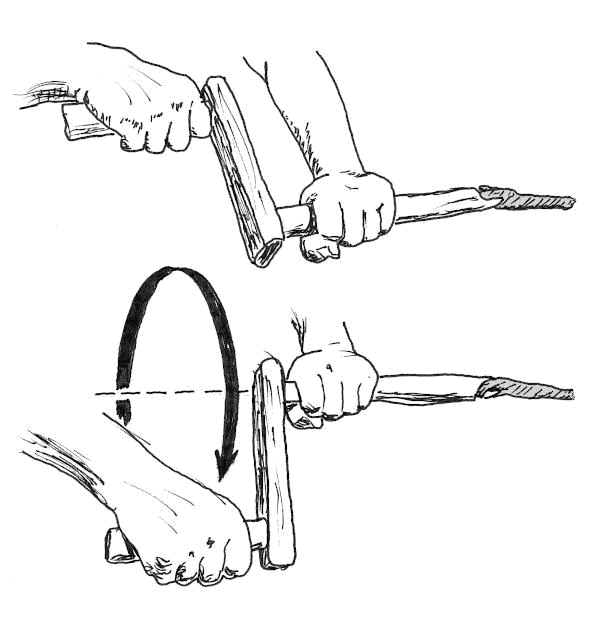

Figure 3.4: Twisting Cord with a Thraw Crook.

The twister twists the crook, while the spinner sits by the supply of straw, and feeds the fibers onto the ever-lengthening cord.

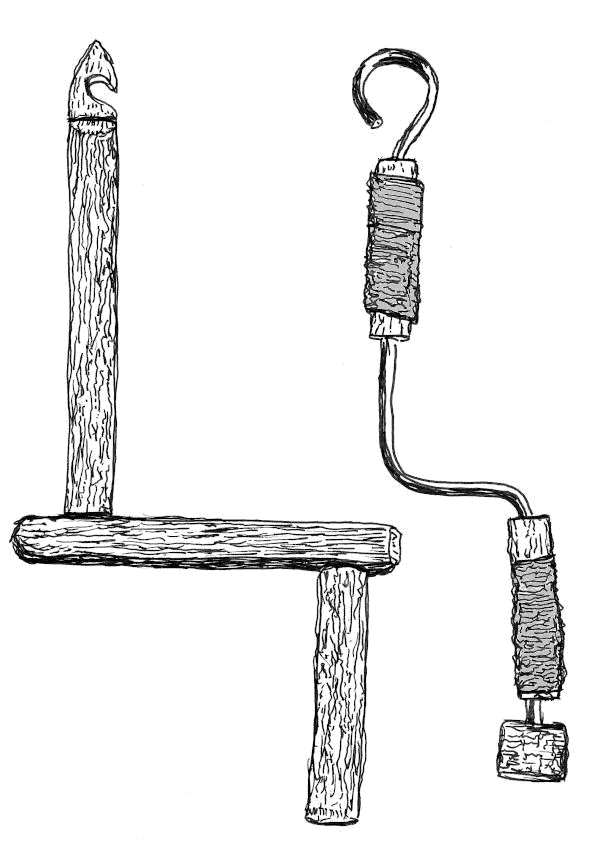

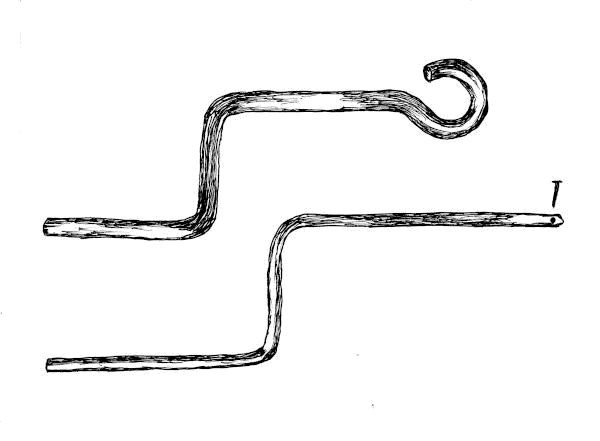

Figure 3.5: Wooden Crank (left), and Wire Crank with Wrapped Wooden Handles (right).

The crank arrived in Roman Europe sometime around 200 A.D.[555] Cranks are also called throw crooks, like the crooks above. Probably since they replaced the older tool that did the same job. This tool can also be called wimble, whimble, or wimbrel. This is probably due to the resemblance to a carpenter's brace and bit which is also called a wimble.[856]

Cranks work on the same principle as crooks, but the positions of the hands are reversed. The pivot hand is closest to the fibers, and the twisting hand is further away.

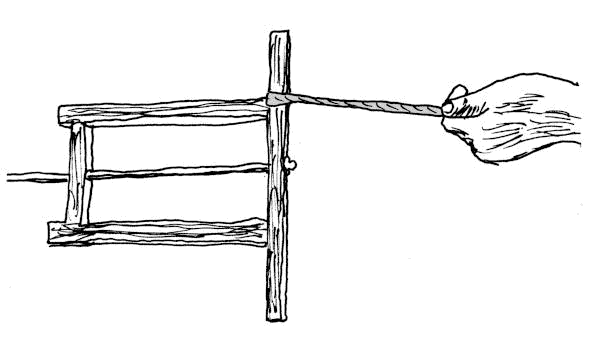

Figure 3.6: Twisting Cord with a Crank or Wimble.

For small ropes, the crank is used in the same manner as the crook, with the twister moving backwards, and the spinner stationary at the fiber supply end of the rope. At ropewalks, where yarns hundreds of yards long were made for ships' ropes, the cranks were stationary, and the spinner walked backwards, with a bundle of fibers wrapped around his waist. Cranks can be either hooked at the end, or provided with a hole for a cross pin. Each has its advantage.

Figure 3.7: Hooked (top) and Pinned (bottom) Cranks.

The hook can support more strain than the cross pin. This is important when working with large ropes and lots of torque. But the hooked crank is difficult to insert into an existing hole. You either have to form the hook after the crank is in place, or the block the crank turns in must be split at the hole.

|

|

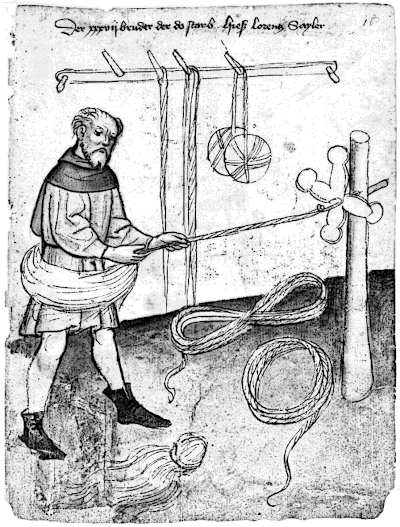

| Figure 3.8: Albrecht Durer.[973] | Medieval Ropemaker [1005] |

At first glance, a ropemaker's reel, sometimes called a "spun yarn winch", looks like something you store rope on once it's been made, not something you use to make rope.[110] [1030] But the ropemaker pushes the forming yarn against one of the "ears" of the reel, causing the reel to turn, and twists the fibers together.[1010] [1014] [1040]

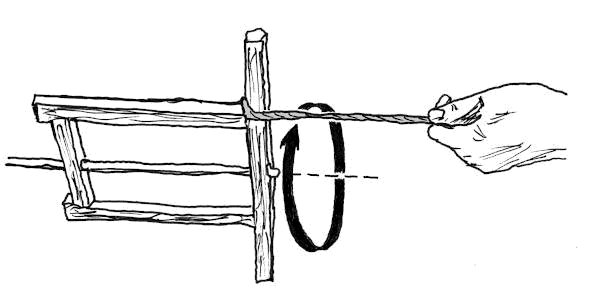

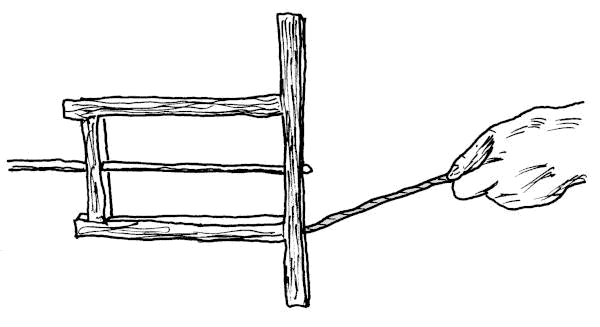

Figure 3.9: Twisting Cord with a Reel.

When the yarn is long "enough", the ropemaker wraps it around the horizontal bars of the reel, and commences spinning again. If the horizontal bars are set at a fraction of a foot or a yard, then it is simple to keep track of how much yarn you've made.

Figure 3.10: Winding Cord onto the Reel, and Twisting Again.

Often the spindle, on which the reel turns, has a sharpened end so it can be driven into any convenient wall or post at the job site.[990]

The great benefit of the reel is that it only requires one person, unlike the crooks and cranks above, or the spinners and wheels below.

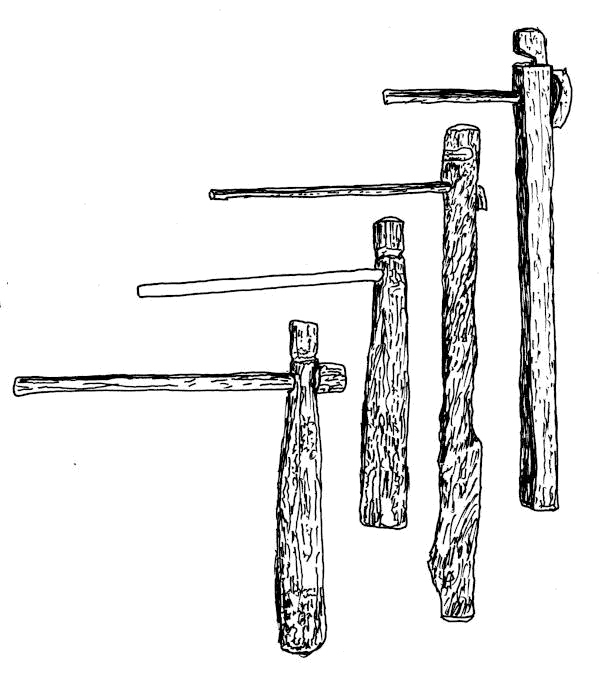

Figure 3.11: An Assortment of Spinners.

Like the crooks and cranks, the person operating the tool just provides the twisting action, and another person, at the other end of the cord adds the new fibers.[977]

Additional names for this type of tool are:

Spinner, Mayan spinner, rakestraw spinner, rope spinner, twister, rope twister, hair twister, twisting paddle, whirligig, tarabilla, tarrabee, tarabi, tarabe, taravia, taravilla, taravita, torteiral or torneiral.[840] [420] [977]

Although a Boy Scouts publication calls this an "Indian Rope Spinner",[305] no pre-Columbian examples have been found. This method of twisting may have been introduced by the Spanish.

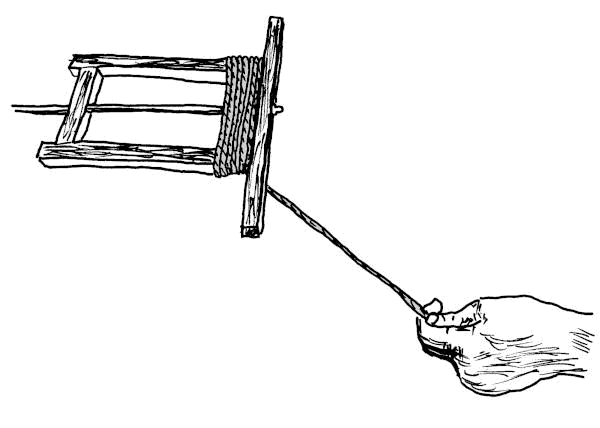

Figure 3.12: Twisting Cord with Spinner.

The spinners I generally use are notched at the top of the stick. These are for twisting yarns into ropes. But some examples are notched under the axle. If you are using the spinner to make yarns from raw fibers, you can wrap the finished yarn around the lower part of the spinner and the new yarn won't get caught in the axle.

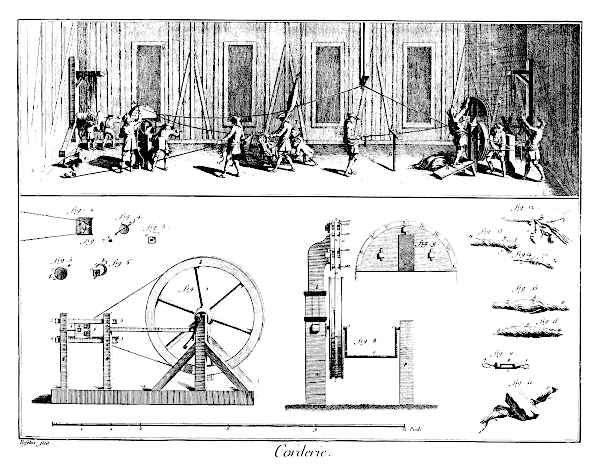

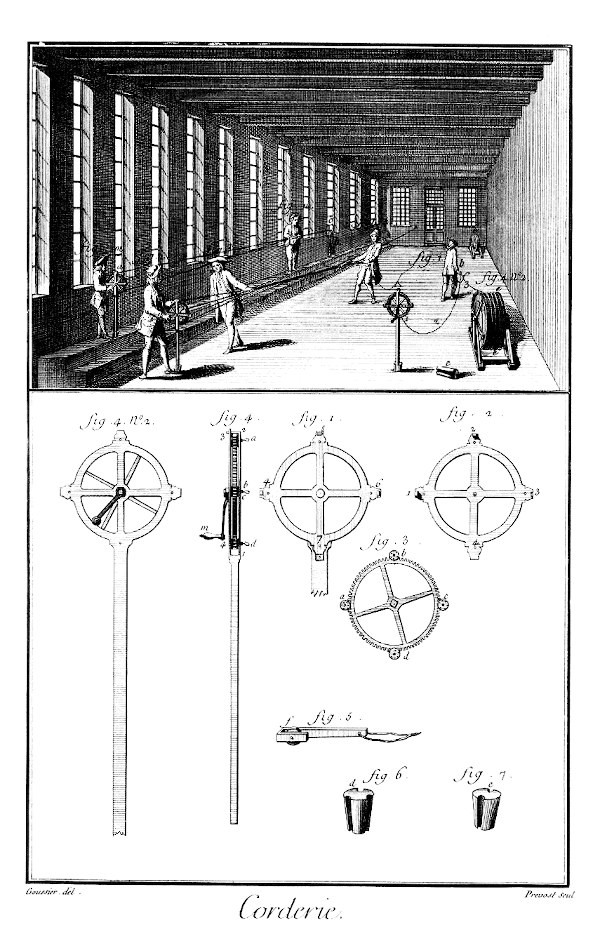

Wheels give the ropemaker the ability to spin more than one yarn at a time, and also turn the spindles at a higher speed than a crank or crook.

A worker, usually a boy apprentice, turned a crank on a wheel which drove several spindles, either by cord bands, or cogs.

Figure 3.13: Diderot and d'Alembert - Band Driven Wheel.[252]

Figure 3.14: Diderot and d'Alembert - Cog Driven Wheel.[252]

Wheels are usually more complicated[1013] , and heavier than cranks, crooks, and spinners, so the wheel stays in a fixed position, and the spinner moves away from the wheel, carrying his supply of fibers with him.

Because the spinner must face the wheel while working, and is always moving backwards as the yarn gets longer, there is an old saying, “you’re behaving like a ropemaker, you’re going backward instead of forward.”[525]

There are other tools for spinning rope yarn that aren't mentioned in the Colonial era texts, but are technically feasible for the period.

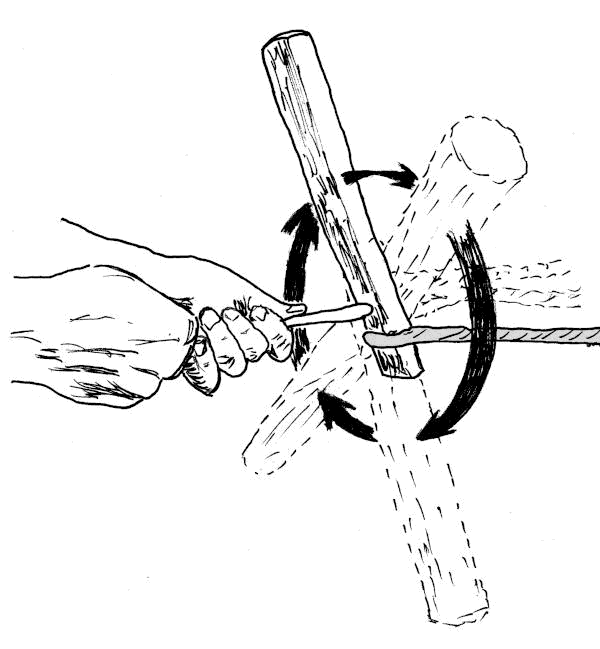

Figure 3.15: Bow Powered Twister

I have only seen this technique in one video from Colombia[959], about five minutes into the clip. I don't even know the correct name for it.

The string is pulled tight against the hook shaft and pulled in one direction, then let slack to move the bow back to the starting position.

| Chapter 2 | Introduction | Chapter 4 |

| Colophon | Contacts |