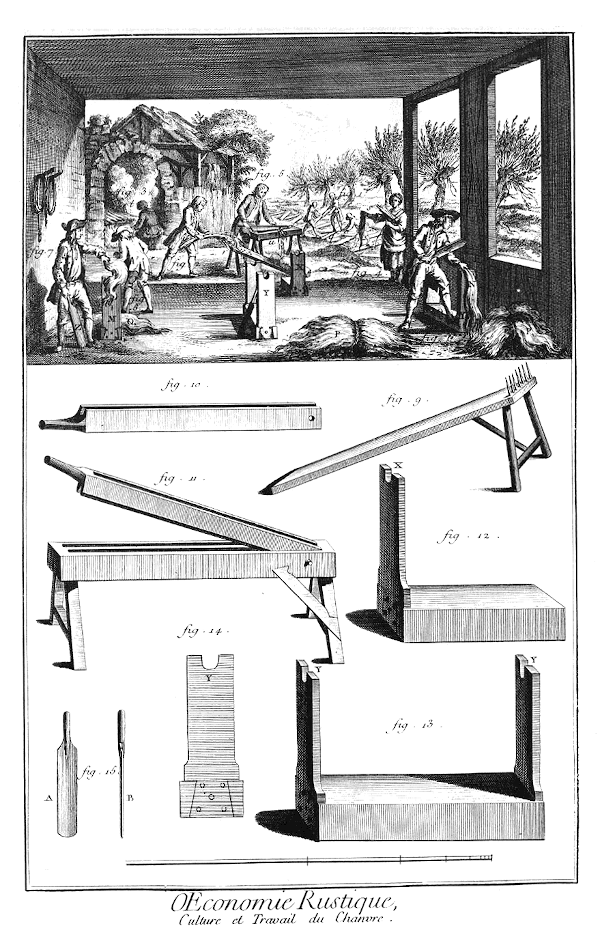

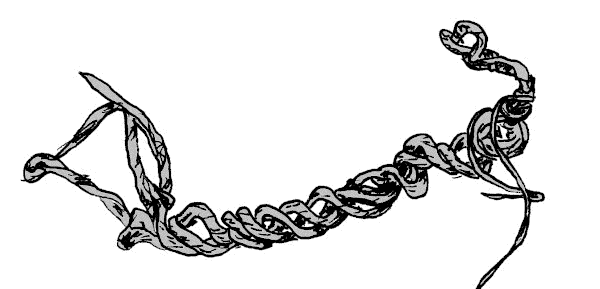

Figure 8.1: Diderot and d'Alembert - Scutching.[252]

| Chapter 7 | Introduction | Chapter 9 |

Before a rope can be spun, the fibers often need to be separated from the rest of the plant. Plants are made up of three basic parts. The fibers you want to keep, the woody parts that make the plant stiff and help it stand up, and the glue that holds everything together.

The fibers are mostly cellulose, the woody parts are lignin, and the glue is pectin. But a Colonial ropemaker wouldn't be familiar with those terms, since cellulose was first identified in 1838 by Anselme Payen, lignin in 1813 by A. P. de Candolle, and pectin in 1825 by Henri Braconnot.

Getting rid of the woody parts can take up a lot of time. The effort you are willing to spend cleaning your fibers depends on how urgently you need that rope. Cleaner fibers mean all the weight of the rope is in the fibers. The woody stuff is just weight, and can cut the fibers of your rope. This is a trade-off you have to weigh. Speed of production against the other necessary qualities of the finished rope.

The ideal plant has lots of long, uniform fibers, only loosely attached to the woody parts. But since we haven't found that plant yet, these are the ways people get everyday plants to give up their fibers.

For a small piece of rope or twine, you can scrape many fibers clean with your thumb-nail, a shell, rock, or a sharp edge of wood. But if you are building a bridge or rigging a ship, your thumb-nail won't last long.

For many bast fiber processes, the material isn't separated into individual fibers, but is worked as long thin ribbons.[105] [290] [613] [777] [1045]

To efficiently clean all this fiber, the European processes brought over by the Colonists consisted of:

A Colonial ropemaker would just say that the water is responsible for loosening the fibers.[328] van Leeuwenhoek first saw bacteria in the 1670s with his microscope, but nobody paid attention for another hundred years. The word "bacterium" was coined in 1828.

There are two types of retting. The first is dew retting where the plants are left out in a dampish field, and turned occasionally. The other is water retting, where the plants are weighted down in a stream or pond.[611] [290] [410]

Retting can take several days, weeks, or even months, depending on your climate. Care must be taken not to over-ret, as that will drastically weaken the fibers.

The bacteria responsible for water retting can be an environmental concern for people downstream. Not just the odor, but the water may become unsafe for human and animal consumption.

Depending on what you are using the rope for, and how soon you need it, retting is often omitted.

Some plants, like yucca and daylilies, have old dead leaves at the base, under the current season's growth. These are naturally retted. Just rub them between your palms to get rid of the woody parts, and you're ready to twist.

For commercial crops like hemp and flax, breaking generally comes after the plants have been retted and dried.

Figure 8.1: Diderot and d'Alembert - Scutching.[252]

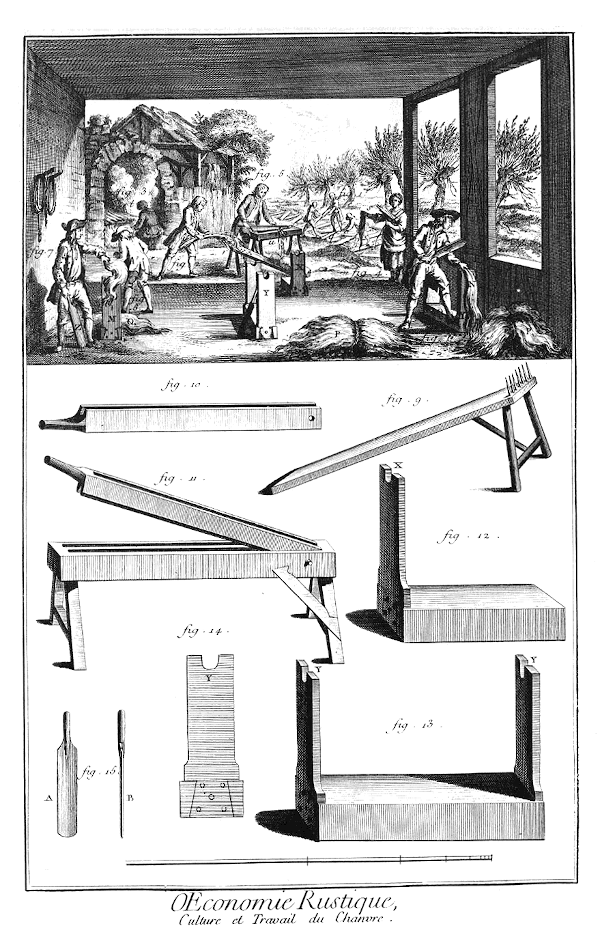

Figure 8.2: Scutching Board with Hemp and Scutching Knife.

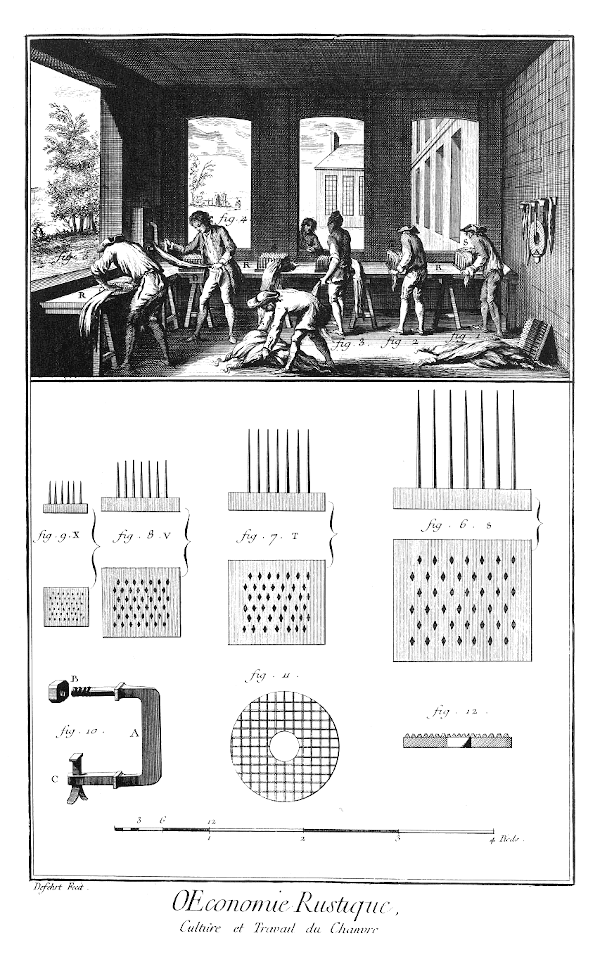

Figure 8.3: Diderot and d'Alembert - Hatchelling.[252]

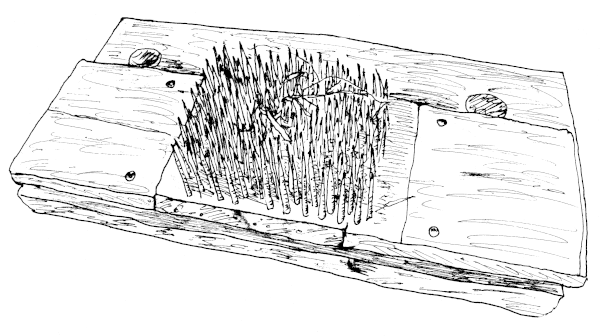

Figure 8.4: Hatchel from Mount Vernon.

Figure 8.5: Shrinkage from Twisting Green Fibers.

If you twist your fibers when the plant is still green, then your rope will become loose as the fibers dry out, as in Figure 8.5, above. Some dried fibers might twist better if they've been briefly soaked in water before spinning. But softening the fibers shouldn't plump them up like they were when green.

If you find yourself with a rope like the one above, it might still be usable when dried if you carefully stretch and twist it. It could be faster than making a new rope from scratch.

More study is needed. Another day.

Keep an eye on the weather. You don't want your raw materials washing down the gutter or blowing into your neighbor's bushes.

| Chapter 7 | Introduction | Chapter 9 |

| Colophon | Contacts |